Damage investigation involves the systematic examination of structures, equipment, components, metal alloys and coatings; use due to corrosion, the environment, abuse, application of the specific material, mechanical failure of any combination thereof. The purpose of such an investigation is to identify the main factors contributing to the failure and managing these factors to prevent the recurrence of the onset of the defect.

The cause of damage to a structure can be used in several ways:

Endures is there for independent technical damage investigation into the cause of failure of damage as a result of, among other things, corrosion, industrial processes, overload and fatigue. However, there is no solution, every situation is different. By combining the technical matters: metallurgy, biology and corrosion, Endures can find the cause and solution of all corrosion-related matters in a very accurate way.

Under the motto “Treat the cause, not the symptom”, Endures offers sustainable solutions aimed to:

Our services for independent damage investigation are used by insurance companies, engineering firms, shipbuilders, oil and gas (petrochemicals), government institutions, the infrastructure sector and water companies.

Would you like to know more about the material durability of your application?

Material selection is choosing a material that best meets specific requirements, determined by factors such as the intended use, the exposed environment and the frequency of use.

Material selection starts with identifying and prioritizing critical design features. These properties may include, for example, strength, wear resistance, elasticity, weight, corrosion resistance, weldability, machinability, conductivity, material cost, etc.

Selecting the right material is essential for achieving maximum service life for your components or structures. Thanks to our specific knowledge in the field of materials science, experience in damage investigation and our extensive capabilities in the field of testing under corrosive conditions, Endures is ideally placed to help you with the appropriate material selection for your application.

Endures helps you select the right material by:

Material failure will often result in damage to assets, or in extreme cases personal injury and/or death to the user. In the aftermath of such a failure, an investigation is started to find and determine the degree of human and legal responsibility for the failure.

As an independant and impartial research intitute, Endures offers a wide range of liability consultancy options. We have the expertise and facilities to determine the key-factors and the timeline of the failure. Such an investigation starts with background research, such as reviewing the manufacturing certificates or reading related case studies and literature. Usually a field inspection is necessary, where the scope and severity of the failure is documented and samples can be taken for further analysis.

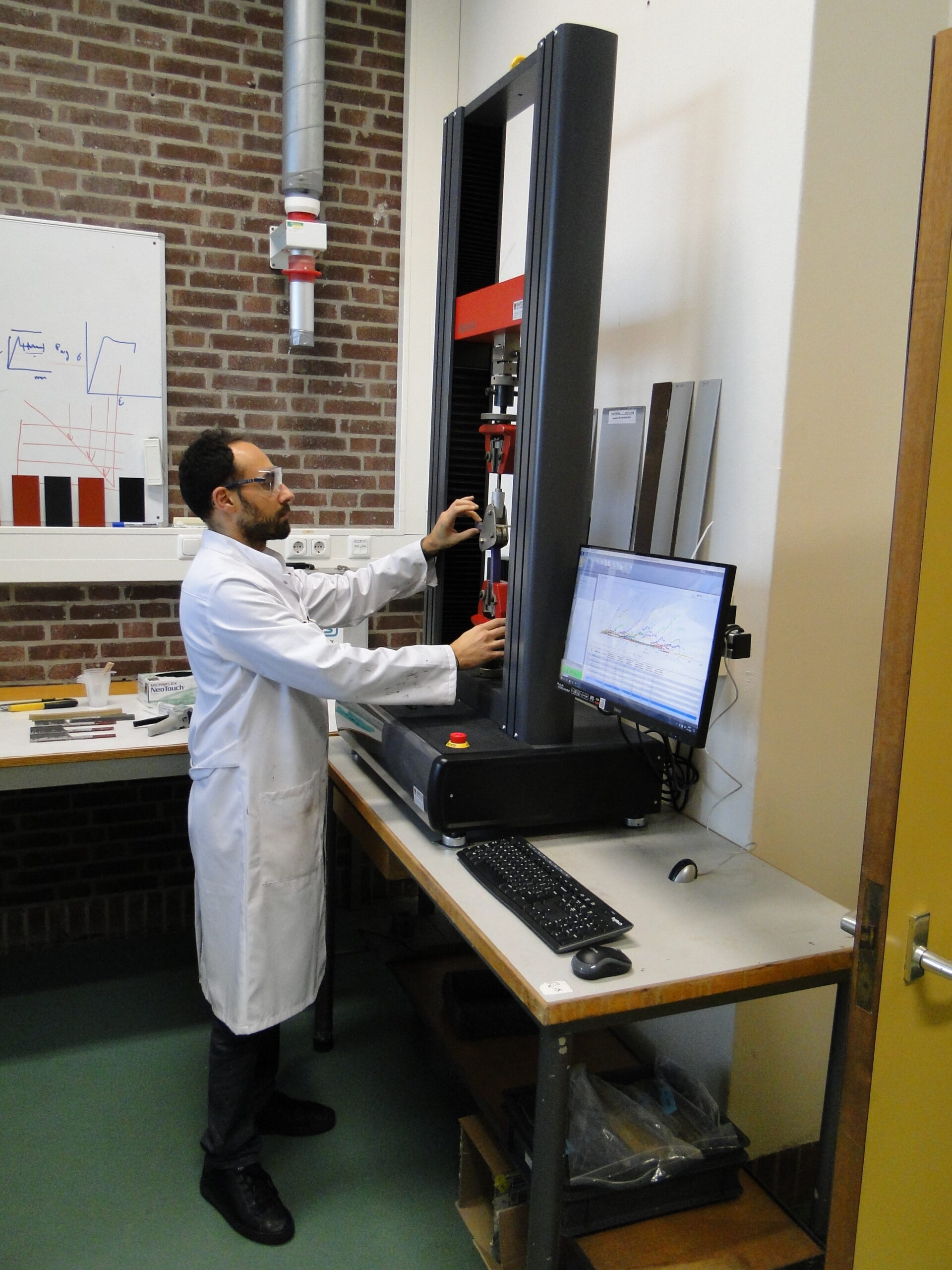

These samples are analysed at our laboratory located in Den Helder, using a wide range of test facilities and equipment. The resulting data is then reviewed and summarized into an official failure analysis report.

Endures has a unique metallurgical and corrosion laboratory with various test facilities in the port of Den Helder with direct access to natural seawater. Here, our experts can perform a wide range of experiments and analyzes using a variety of techniques and equipment, including: