Depending on the source and the research, it is stated that we have an annual damage of 3% to 4% of our GDP due to corrosion, a sloppy 17 to 18 billion € on an annual basis, in the Netherlands alone! New calculations in the USA even refer to 6.2% of GDP due to corrosion damage! You would expect preventing its emergence to be high on the political agenda, nothing could be further from the truth.

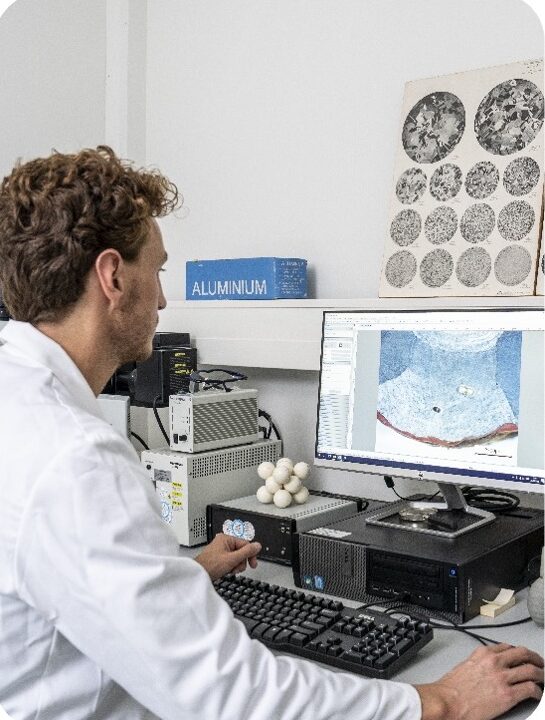

Corrosion and corrosion damage can be prevented by using the expertise of Endures. Endures has engineers and experts for research into corrosion damage, but also has the expertise to think along with you in product development, design, material selection to prevent damage, in other words corrosion prevention.

What is Corrosion?

The most common form is electrochemical or also called wet corrosion. The definition of corrosion is:

Corrosion is an undesirable chemical or electrochemical attack on a material.

or:

Corrosion is an (electro) chemical reaction of a material with its environment, which adversely affects its properties.

Nature strives for balance, that is to say for the lowest possible energy state. We humans put extra energy into our products and nature does everything in its power to nullify this with corrosion (damage) as a result. This process is therefore undesirable and is actually the oxidation of a metal. With steel we call this oxidation: rusting. The oxidation of steel in wet corrosion produces rust.

In order to achieve good prevention it is necessary to understand the corrosion process and thus the types and forms of corrosion. Wet Corrosion comes in many different forms. Usually, the following forms are distinguished for metals:

MIC (Microbial Induced Corrosion), popularly called mic corrosion.

A common form of wet corrosion is galvanic corrosion. Galvanic corrosion an electrochemical process in which one metal corrodes when in contact with another metal, an electrolyte is present and the potential difference between the two metals is equal to or greater than 0.2V (depending on the conductivity and aggressiveness of the environment ). In other words, one metal sacrifices itself in favor of the other metal.

If it is undesirable, it is called galvanic corrosion. If desired, it is called Cathodic protection.

Some examples of galvanic corrosion are:

Galvanic corrosion of aluminum and stainless steel in seawater, where the aluminum will dissolve to protect the stainless steel.

Prevention of Galvanic Corrosion

Galvanic corrosion can be prevented to a limited extent by, among other things:

Connect a third (more anodic = "lesser") metal (which "sacrifices itself") to the other two, so that both of them remain (Cathodic protection).

Avoid metallic contact (electrically insulating);

Choose metals that are close to each other in the voltage series (even better is to use the galvanic series);