Home » Case studies » MIC on metallic coated and uncoated steel exposed to offshore sediments.

Will MIC develop on bare steel within (offshore) soil samples from the site?

Will MIC develop on steel coupons covered with a metallic coating exposed to (offshore) soil samples from the site?

Three different materials were sampled:

The samples were exposed to the following media:

The samples were then incubated in their respective conditions for a 6 month period before compared.

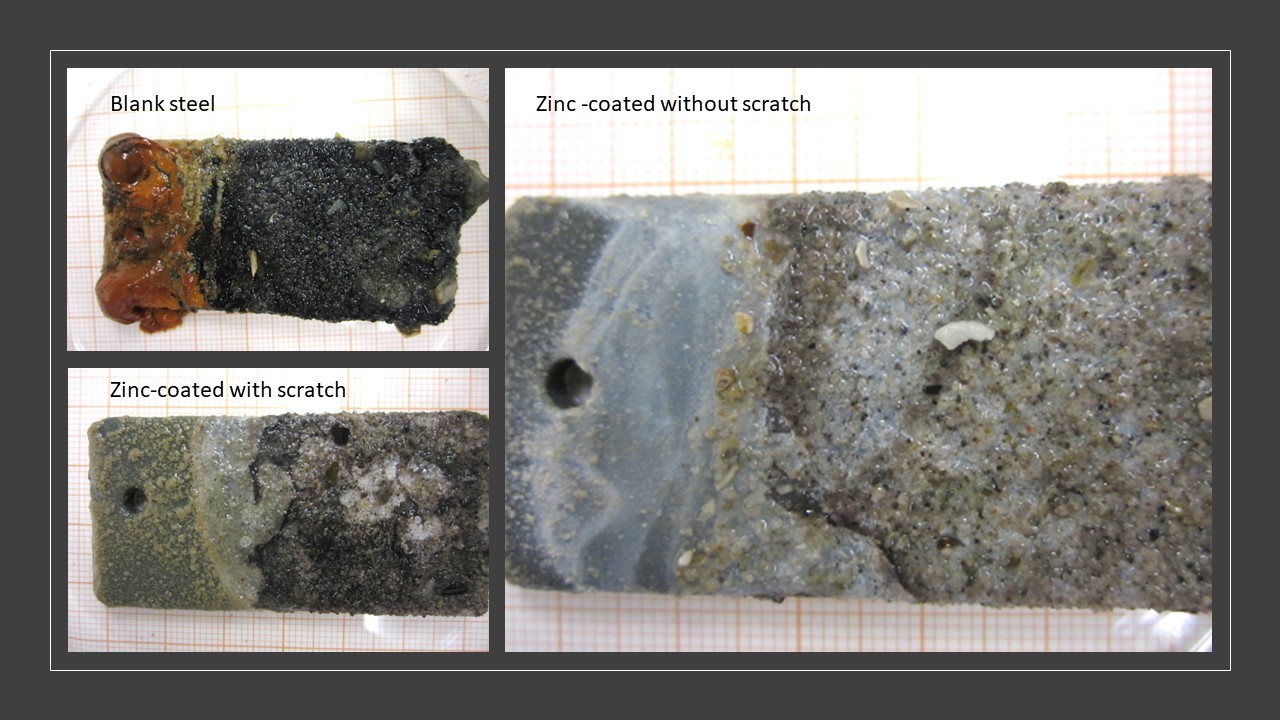

Visual inspection of blank steel coupons after 6 months of incubation revealed rusty-brown corrosion products and tubercles in the area which was exposed to seawater whereas the area which was exposed to the sediment showed blackish brown corrosion products.

The zinc-coated coupons (with and without scratch) showed white precipitations at the water-sediment interface and in the area which was exposed to the sediment.

Only the corrosion products of the blank steel coupon showed presence of MIC relevant microorganisms: sulfate-reducing bacteria (SRB), acid-producing bacteria (APB) and iron-reducing bacteria (IRB). SEM-EDX analysis showed presence of Fe, O, which explains the rusty-brown color of iron(III)oxides and S was detectable which forms with Fe the black precipitations, iron sulfide (FeS).

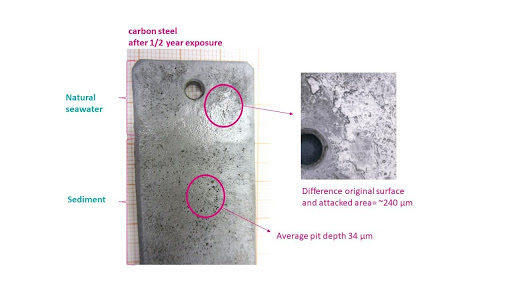

Blank steel coupons showed a corrosion rate of 0.06 mm/year and pitting was found. The average pit depth was 34 µm on part of the coupon exposed to sediment and 240 µm on the water-sediment interphase. Presence of MIC relevant microorganisms, sulfur in the corrosion products and pitting corrosion is an indication that MIC is present and active on the coupon surface, especially in the water-sediment interphase.

On the zinc-coated coupons with and without scratch no MIC relevant microorganisms were detected. SEM analysis showed presence of O, Zn, Mg and Al which explains the white precipitations (mainly zinc oxides) on the coupons. No weight loss and no pitting was found on zinc-coated coupons.

The zinc containing product forms an oxide layer which protects the steel against (microbial) corrosion whereas the blank steel coupon showed (microbial) corrosion. Conducting microbiological research at an early stage will significantly improve corrosion protection