Home » Case studies » MIC in quay wall of harbor

What is causing damage to the old parts of the harbor quay wall?

To this end a comprehensive failure analysis package was carried out on the structure:

Such approach will allow a thorough diagnosis and analysis for concluding if MIC is really the root cause of the damage observed. From this also proper recommendations can be given for mitigation of the problem.

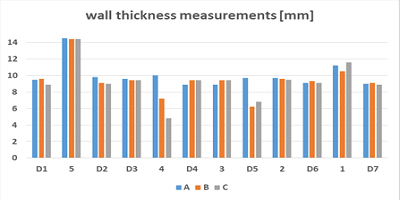

After inspection of the quay wall potential and wall thickness measurements were performed. Next to it corrosion product samples were taken for microbial analysis and microbial related failure analysis (SEM-EDX and volatile sulfide determination).

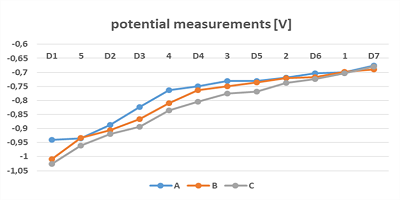

Results showed that corrosion related microorganisms were frequently found in corrosion products scratched from the surface. Sulfur was found in corrosion products indicating possible activity of SRB directly at the damaged surface and detection of gaseous sulfide from corrosion product samples confirmed this. Potential measurements showed variable values between -0.7 and -1.02 V vs sat Ag/AgCl Sacrificial anodes were placed only on the new part of the structure (D1).

Along the older part the potential was not low enough, resulting in severe corrosion damage and large perforations whereas the new part was adequately protected by the sacrificial anodes.

All this leads to the conclusion that MIC plays a role in the observed damage of the quay wall structure and that the part where anodes are installed are protected against microbial activity if the potential is lower -0.9 V vs sat Ag/AgCl.

The old structure should be cleaned and sacrificial anodes should be placed as well on the old parts of the quay wall until it will be renewed in future. Potential should be monitored and a value lower than -0.9 V vs sat Ag/AgCl should be present to protect the structure at the inspected location under the given environmental circumstances.