During the inspection in the installation cellar, some tubercles were found on the inside of the flange where the pump is mounted. Customer question: Is the pitting corrosion found caused by MIC?

During this test the minimum speed for self-cleaning of marine fouling hull coatings is assessed through static exposure and rotating drum testing of coated panels in seawater

On several vessels, pipes immediately adjacent to a heat exchanger were perforated and leaking. Inspection of the pipes of all heat exchangers showed heavy corrosion and indicated that similar perforations could occur. Customer question: What causes early failure of components?

Investigation of a MIC failure case in a marine/brackish harbor in The Netherlands. The quay wall consisted of an old part without and a new part with sacrificial anodes. Aim of the investigation was to find the root cause of failure of sheet pilings in the old part.

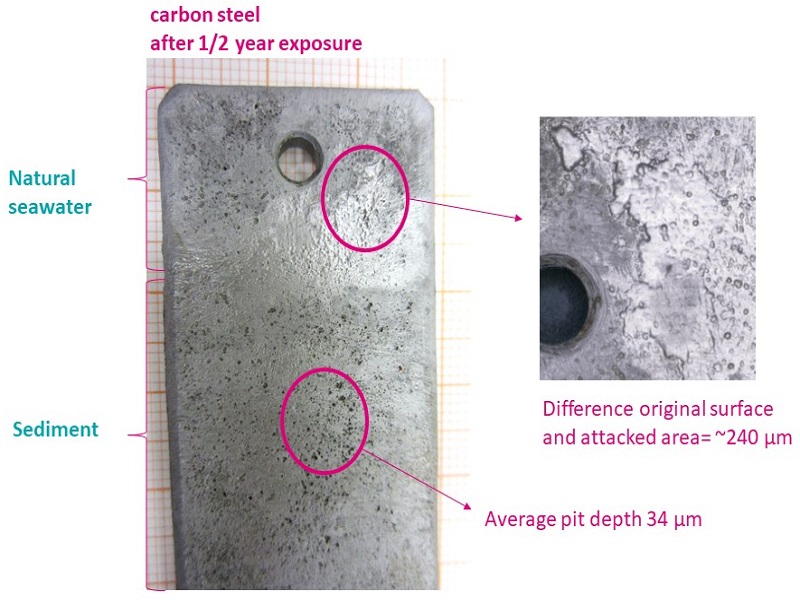

Visual inspection of uncoated steel coupons revealed rust brown colored corrosion products and tubercles on the parts exposed to seawater, after 6 months of incubation